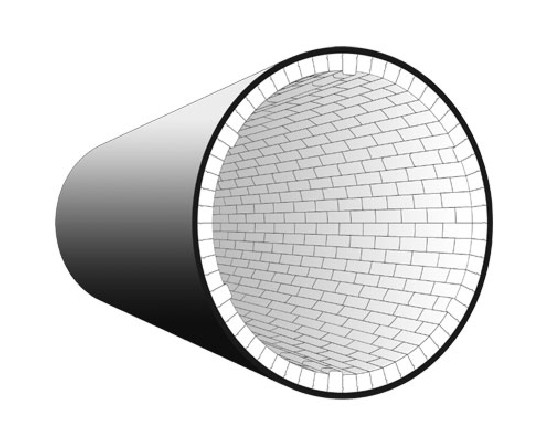

The Alumina lining bricks are used as the lining in the ball mill of ceramic industry, cement industry, paint industry, pigment industry chemical industry and pharmaceutical industry.

Using this liner will effectively improve grinding efficiency, reduce grinding cost, it is considered to be the best choice for ball mill lining.

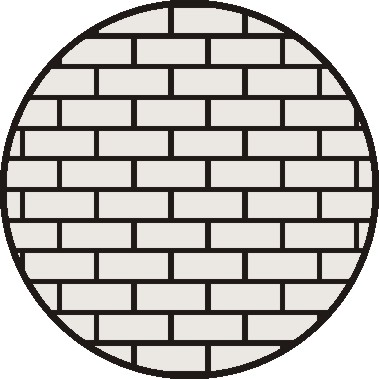

Betore installation, all the partial remaining of bricks and cement on the inner surface should be completely removed, the smooth surface should be made hoarse, damaged iron, surface should be repaired through welding ifit is badly worn.

For installation, grout width should be about Imm using 425# white cement. Brick should be laid from level area of ball mill and moving upward. Surface area should be clean and kept wet by spraying water for 1 to 2 days to increase the cohesion for max hardhess, Finally, the ball millshould be filled with water for minimum of 10 days.

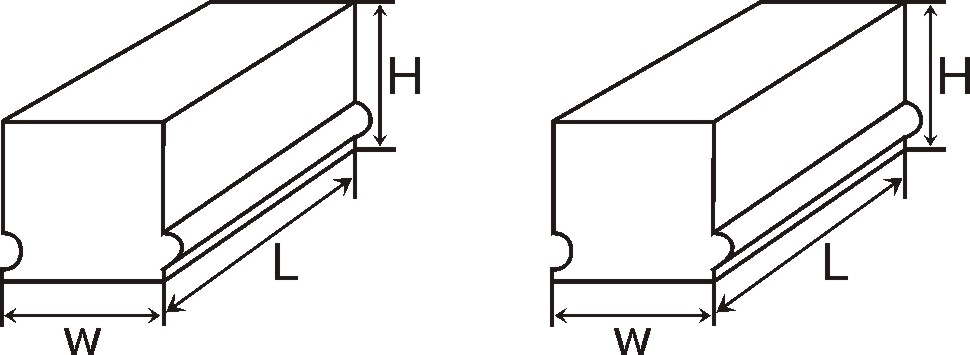

| Size | Length(mm) | Width(mm) | Height(mm) |

|---|---|---|---|

| Straight brick | 150 | 50 | 40/50/60/70/90 |

| Trapezoide brick | 150 | 45/40 | 40/50/60/70/90 |

| Half straight brick | 75 | 50 | 40/50/60/70/90 |

| Half trapezoide brick | 75 | 45/40 | 40/50/60/70/90 |

| Flacks | 150 | 25 | 40/50/60/70/90 |